Ultimate Guide to Hydro Excavation

by TRUVAC Team, on Apr 2, 2024 7:15:00 AM

Hydro excavation, also known as hydrovac, is a process of removing soil and debris using pressurized water and a powerful vacuum. This high-pressure water jet and suction equipment allows for precise excavation without causing damage to underground utilities and tree roots.

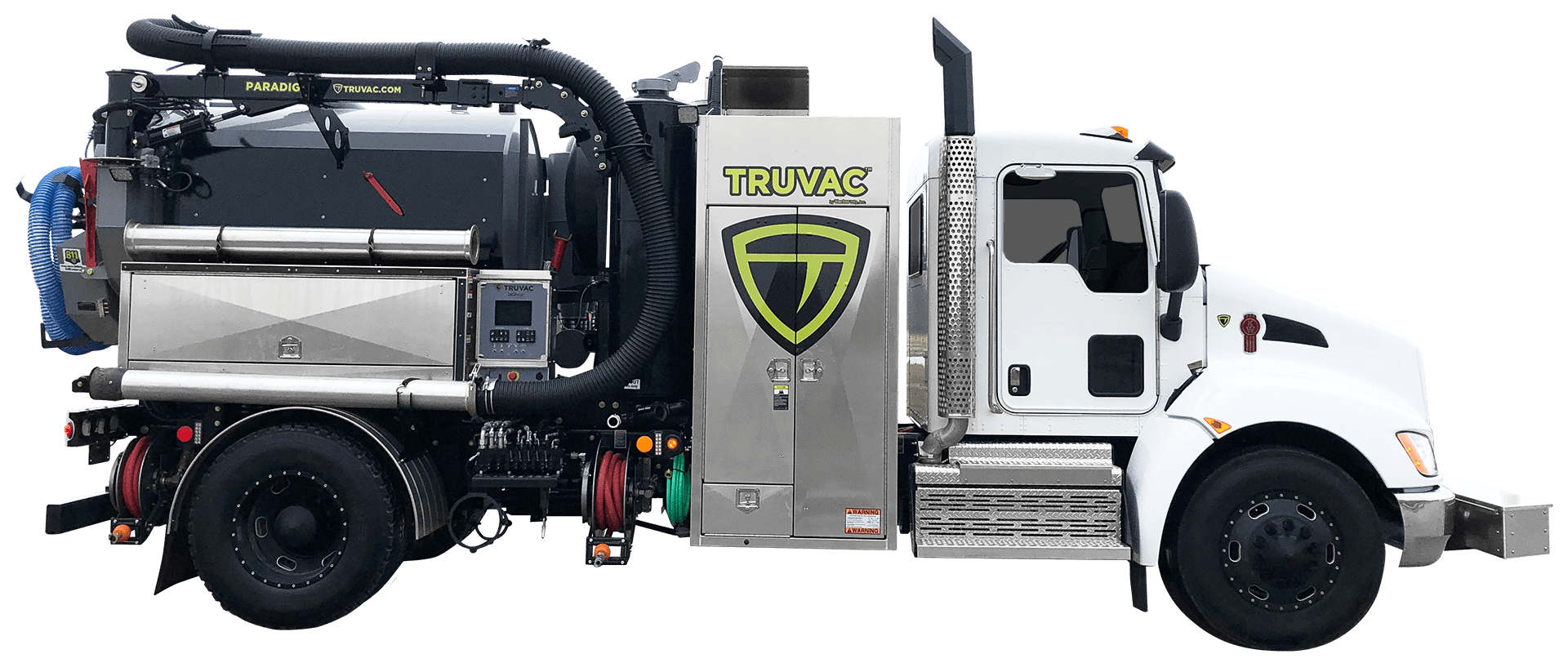

Hydrovac equipment ranges from smaller, more maneuverable trailers and non-CDL trucks to larger, high-capacity industrial-grade trucks. The capabilities of these trucks include a range of tank sizes, water pressure levels, vacuum power, and boom reach.

Common applications of hydro excavators include utility potholing, trenching, slot trenching, and daylighting. When choosing the right hydro excavator for a specific job, factors to consider include the type of soil, job site conditions, required reach, capacity, as well as water and debris disposal options. Choosing the right hydro excavation truck is essential to ensure efficiency and safety in excavation projects.

How Hydro Excavation Works

Hydro excavation is a non-destructive digging method that uses a combination of high-pressure water and an air vacuum to cut through and break up soils. The high-pressure water is directed into the soil, turning it into a slurry, which is then removed from the excavation area by the air vacuum. The slurry is transferred to a debris tank for later disposal.

The air vacuum is powered by a fan system or a positive displacement blower, which creates a powerful suction force to remove the slurry from the excavation site. The use of the fan system or positive displacement blower ensures that the debris is efficiently and effectively removed from the site, leaving a clean and precise excavation area.

Imagine trying to safely dig around fiber optic cables with a shovel or backhoe

Overall, hydro excavation offers a safe and precise alternative to traditional excavation methods, providing a highly efficient way to excavate soil without causing damage to underground utilities or other surrounding structures. The use of high-pressure water and an air vacuum, along with a fan system or positive displacement blower, make hydro excavation a versatile and effective method for a wide range of excavation projects.

How does vacuum excavation work for underground utility location

Vacuum excavation is a method used to locate underground utilities by using high-pressure water and an air vacuum.

When it comes to the vacuum source, there are two main options to choose from: a fan system or a positive displacement (PD) blower. PD blowers are the most popular option due to their ability to pull wet/heavy material over long distances. Fan units are able to generate high airflow, making it suitable for a wide range of soil types.

How does vacuum excavation compare in terms of cost and efficiency to traditional excavation methods?

In terms of cost, vacuum excavation requires less labor as it typically only requires a two-person crew, whereas traditional excavation methods usually require more workers. Additionally, the use of vacuum excavation reduces the need for backfill materials, further decreasing costs.

Furthermore, vacuum excavation has a lower environmental impact as it minimizes disturbance to surrounding areas and soils, as well as reduces the risk of damaging underground utilities. Traditional excavation methods, on the other hand, often result in more extensive and disruptive excavation, leading to a higher environmental impact.

When it comes to efficiency, vacuum excavation is quicker and requires less time to locate, expose, and repair underground utilities. Traditional excavation methods can be more time-consuming and labor-intensive.

In terms of safety, vacuum excavation is non-destructive and carries a lower risk of accidents or injuries compared to traditional excavation methods. The use of precise equipment and technology minimizes the potential for accidents and damage to existing infrastructure.

On the other hand, the upfront initial cost of a hydro excavator machine may be greater than a traditional mechanical digger and require slightly more operator training.

However, hydro excavation proves to be more cost-effective over the long term, in addition to being more efficient and safer than traditional excavation methods.

What are the disadvantages of hydro excavation, if any?

Hydro excavation, while an efficient and non-destructive excavation method, has its own set of disadvantages. One such disadvantage is the need for designated dumping locations for the excavated material. The slurry produced during hydro excavation cannot be easily disposed of just anywhere, requiring specific dumping sites and adherence to environmental regulations.

Furthermore, the inability to reuse the excavated material can be seen as a potential drawback of hydro excavation. Unlike traditional excavation methods where the soil or debris can be repurposed or used in backfilling, the sludge, slurry, and ooze from hydro excavation is typically deemed unusable, resulting in additional disposal costs and environmental impact. Learn the differences between Hydro vs Air Excavation.

In comparison to alternate excavation methods such as traditional mechanical excavation, these disadvantages may not be as significant. Mechanical excavation may not require designated dumping locations, and the excavated material can potentially be reused. However, it is important to consider other inefficiencies of alternate methods, such as potential damage to underground utilities and the higher risk of worker injury.

It is important to weigh these drawbacks against the inefficiencies of alternate excavation methods when selecting the most suitable approach for a specific project.

Is hydro excavation safe?

In addition to being safe for surrounding environments and structures, hydro excavation also promotes worker safety by minimizing the need for manual labor and reducing the risk of cave-ins and collapses.

Daylighting or Exposing Utilities

Daylighting or exposing utilities is the process of locating and uncovering underground utilities without causing damage to them. Hydro excavation is commonly used for this purpose.

The first step in the process is to identify the area where the underground utilities are located. Once the area is identified, a hydro excavation truck is brought to the site to dig out the terrain.

By using hydro excavation for daylighting, the horizontal location of underground utilities can be accurately determined while minimizing the potential for costly damage. This process is not only safe and efficient, but also minimizes disruption to surrounding areas.

Debris Removal

Hydro excavation trucks are a powerful and efficient tool for removing debris and cleaning out structures, while minimizing impact on surrounding areas. The flexibility and maneuverability provided by the boom component allow these trucks to access difficult-to-reach areas and remove debris with precision. In urban areas or locations with limited space, the maneuverability of hydro excavation trucks is especially beneficial, as they can navigate tight spaces without causing damage to the surrounding environment.

The high-pressure water jets used in hydro excavation can effectively remove both wet and dry debris, including rough materials such as rocks and sand. This makes it a versatile option for various clean-up tasks.

Overall, hydro excavation trucks are an effective and environmentally friendly solution for cleaning out structures and removing debris, thanks to their flexibility, maneuverability, and ability to deal with rough debris.

Piling Hole Excavation

Piling hole excavation is a critical process in construction and foundation work. Hydro excavation trucks are often used for their precision in digging various diameters and depths. These trucks precisely remove the soil, ensuring accurate piling hole excavation.

Matching the blower lift to the depth of the excavation is crucial for successful piling hole excavation. The blower lift refers to the force of the vacuum that lifts the soil. It must be properly matched to the depth of the excavation to ensure efficient and thorough removal of soil without causing damage to the surrounding area.

The necessary steps for piling hole excavation include site preparation, marking the excavation area, and using the hydro excavation trucks to precisely dig the holes. Proper safety measures are also essential, as well as equipment such as safety barriers, personal protective gear, and shoring equipment for deep excavations.

Piling hole excavation using hydro excavation trucks ensures precision in digging various diameters and depths, while matching the blower lift to the depth of the excavation is crucial for successful and efficient soil removal. This process is essential for laying the groundwork for sturdy and reliable foundations.

Cold Weather Digging

In cold weather conditions, performing hydro excavation requires the use of heated water to effectively break up frozen soil. To do this, start by ensuring that the hydrovac unit's water is heated to the appropriate temperature for the specific freezing conditions. This heated water will help to melt the frozen soil, making it easier to suction out.

Hydrovac units are designed to have the capability to maintain a consistent water temperature, even in freezing temperatures. They are equipped with powerful heaters that can heat the water to the required temperature, allowing for efficient excavation in cold weather. Additionally, the high-powered vacuum system of the hydrovac unit can easily remove the liquefied soil from the excavation area. This technology also reduces the risk of injury to workers, as it eliminates the need for manual digging in extremely cold conditions – when accidents are more likely.

What are some tips on how to choose the right hydrovac truck for a job?

When it comes to choosing the right hydrovac truck for a job, there are several key factors to consider. From the size and capacity of the truck to the available features and capabilities, making the right choice is crucial for a successful project. By assessing the specific demands of the job, as well as the terrain and environmental conditions, operators can ensure they select the most suitable hydrovac truck for their needs. Below are some useful tips to consider when choosing the right hydrovac truck for a job.

What is the capacity of a hydro excavation truck?

A hydro excavation truck is designed for precise excavation and debris removal in tight spaces. The debris body capacity typically ranges from 5 to 15 cubic yards, allowing for efficient removal of soil, rocks, and other materials. The boom reach of a hydro excavation truck can extend up to 24 feet, providing extensive reach and maneuverability for excavation projects. The vacuum system is equipped with a powerful blower and filtration system, capable of suctioning up to 6,000 cubic feet of material per minute. The water system capacity ranges from 200 to 1,200 gallons, providing ample water supply for pressurized excavation and debris removal. Additionally, hydro excavation trucks are equipped with advanced control systems, temperature and pressure monitoring, and safety features to ensure smooth and precise operation.

How much PSI is needed for hydro excavation?

The recommended psi for hydro excavation typically falls within the range of 2,000 to 3,000 psi. This pressure range is ideal for effectively breaking up soil and efficiently removing debris during the excavation process.

The pressure level plays a crucial role in the efficiency and safety of the excavation. Higher psi levels can result in faster excavation and increased productivity, but they also carry a greater risk of damaging underground utilities or causing injury to workers. Lower psi levels may require more time and effort to complete the excavation, but they reduce the risk of accidents and minimize potential damage to surrounding infrastructure.

When determining the appropriate psi for different soil types and excavation depths, several key factors should be considered. Soil density, moisture content, and the presence of rocks or other obstructions will all influence the ideal pressure level for effective excavation. Additionally, the depth of the excavation will impact the required PSI, with deeper excavations often necessitating higher pressure levels to effectively penetrate and remove the soil. Understanding these factors is essential for selecting the optimal PSI to ensure efficient and safe hydro excavation.

Ground Conditions

The specific ground conditions, such as sandy soil or frozen dirt, can significantly impact tank maintenance activities. Sandy soil presents a challenge for debris removal, as the loose and granular nature of the soil makes it easy for debris to accumulate and difficult to remove. In contrast, frozen ground poses difficulties due to the inability to penetrate the ground for maintenance activities. In such cases, hot water is necessary to melt the ice and allow for access to the tank.

When addressing ground conditions, a key factor to consider is the impact of weather on soil conditions. For example, heavy rain can cause sandy soil to become compacted, making it easier to remove debris, while freezing temperatures can lead to frozen ground, requiring additional steps for maintenance. Overall, understanding the specific ground conditions and how they are influenced by the weather is crucial for effective tank maintenance.

Distance from the Truck

When working at a distance of 200 ft or less from the truck, a standard blower may suffice for most tasks. However, when the work site is further away, such as at a distance of 600 ft, a more powerful blower is needed to ensure efficient and effective completion of the task. This need for a powerful blower is especially critical in rear easement or vacuum excavation work, where precision and thoroughness are required. The distance from the truck affects the effectiveness of the blower in directing and controlling the airflow, which in turn impacts the ability to remove debris or excavate material with accuracy. Therefore, it is crucial to have a more powerful blower when working at greater distances from the truck to maintain the desired level of precision and productivity in the task at hand.

Depth of Excavation

The depth of excavation is a critical factor when considering hydro excavation equipment and techniques. When dealing with deep excavations, such as piling holes that are 20 feet deep, it is essential to use equipment and methods that can efficiently and effectively handle such depths.

In deep excavations, the need for a blower that matches the required lift becomes crucial. The blower is responsible for creating the vacuum necessary to remove soil and debris from the excavation site. When dealing with deep excavations, a blower with a higher lift capacity is necessary to ensure that the soil and debris can be effectively removed from the deeper levels.

Dump Location

When using a dump location, it is important to be aware of the proper dump height and control requirements for the truck. The dump height refers to the maximum height at which the truck’s container should be raised before dumping its contents. It is essential to adhere to this height in order to ensure the safety of the surrounding environment and personnel.

Control requirements for the truck include the need for a skilled operator who can maneuver the vehicle with precision and caution. This may involve using a control panel to raise and lower the container, as well as being aware of any obstacles or hazards in the dump environment.

It is also crucial to be aware of other containers, personnel, or equipment in the vicinity. Being conscious of the surroundings and communicating effectively with others can help prevent accidents and ensure a smooth and efficient dumping process.

These measures are vital for ensuring a safe and productive dump for all involved.

State & Federal Bridge Laws for Hydrovac Trucks

State and federal bridge laws for commercial vehicles like hydro excavators regulate the weight that a truck can carry and where it can travel based on the structural capacity of bridges. These laws vary by state, with each state having its own regulations regarding weight limits and bridge restrictions for commercial vehicles.

Federal regulations set a maximum weight limit of 80,000 pounds for commercial trucks, including the tractor, trailer, and cargo. Each state may have its own specific weight limits for trucks traveling on highways and bridges within its borders.

Additionally, states may have bridge formula laws that take into account the length of the truck, the number of axles, and the spacing between the axles to determine the maximum allowable weight for that specific truck. Trucks that exceed these weight limits may be subject to fines and penalties.

It is important for commercial truck drivers and companies to be aware of and compliant with both state and federal bridge laws to ensure safety on the roads and prevent damage to bridges and infrastructure. Drivers should be familiar with the regulations in each state they will be traveling through to avoid violating any weight restrictions or bridge laws.

Conclusion and Next Steps

Hydro Excavation is not only safer and more efficient than traditional digging but allows operators to continue working even in harsh and frozen environments. However, operators must still undergo the necessary training and certification, as well as be mindful of local and federal restrictions and guidelines pertaining to the removal, transport, and disposal of material, as well as the truck itself.

The options and features described above can help give hydro excavator companies an edge in a growing field. The use of professional hydro excavation equipment can lead to safer and more efficient job sites in a variety of applications.

We want to hear your stories. Send us pictures of your TRUVAC hydro excavator in action! Email emarketing@federalsignal.com