Combatting Inaccurate Utility Markings

by TRUVAC Team, on Feb 17, 2022 12:38:18 PM

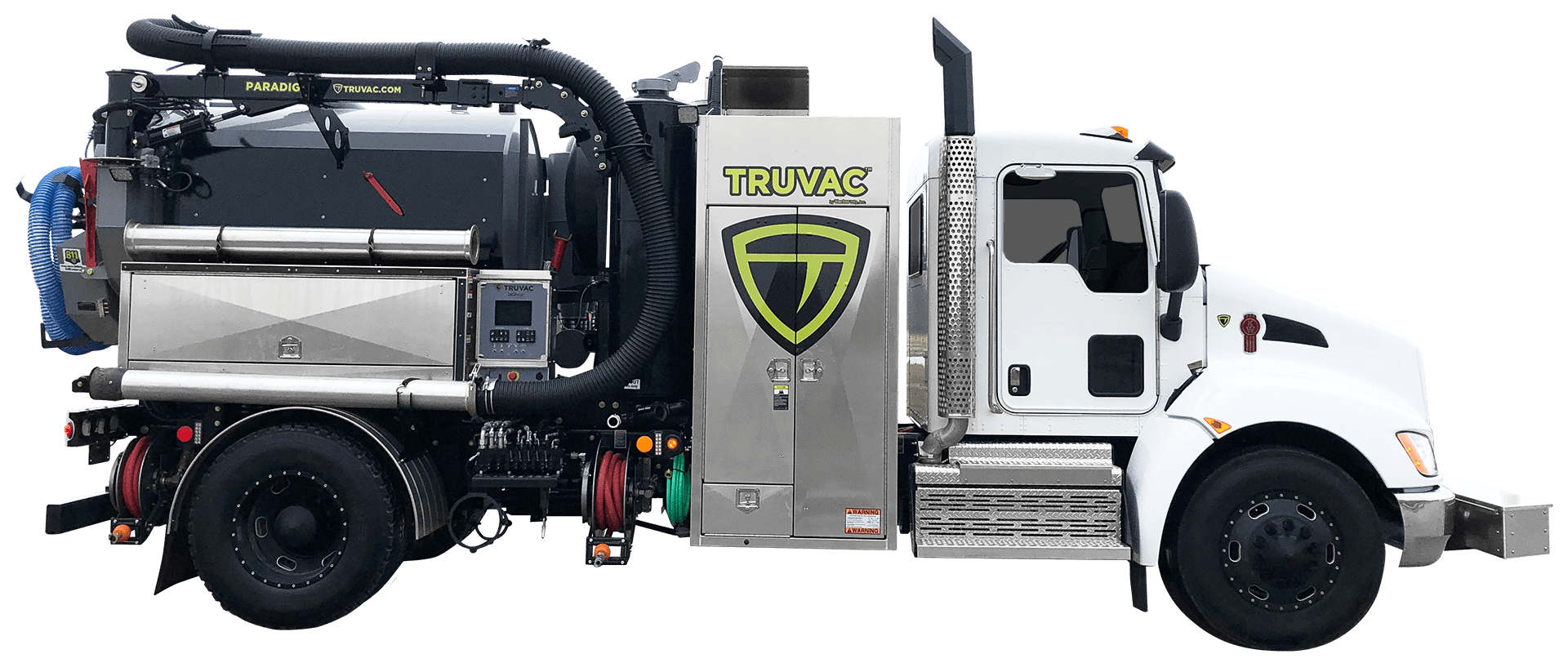

The TRUVAC® FLXX™ midsize vacuum excavator designed to be easily maneuverable in locations like this new housing development, backfilled with red clay soil, in Georgia.

The best plan of attack to locate underground utilities and reduce risk of damage is to consider mapped utility locations and marking flags as “suggested” locations for those utilities. Despite good intentions, maps and location methods rarely provide an exact location, nor the precise depth, of a utility line below ground. Verification of utility locations is ultimately confirmed visually on the jobsite when the underground facilities have been exposed using extremely efficient vacuum excavation equipment.

Vacuum excavation provides a more precise, less destructive, and safer method for “daylighting.” “Daylighting” is the term to describe digging to expose and visually confirm the location of underground utilities. Vacuum excavation can be performed with either pressurized air or water in addition to an industrial strength vacuum to simultaneously excavate and evacuate the soil spoils back into the debris body of the vacuum excavator. This minimally invasive method of excavation exposes the underground utilities with speed and minimizes damages in borehole and trenching applications.

Avoid Damage to Critical Infrastructure

Damage prevention remains the primary goal in underground utility location and digging surrounding underground infrastructure installations, repairs, and rehabilitation. Experienced utility contractors agree that the best weapon to combat inaccurate utility markings is to expect the unexpected. This means acknowledging that pre-plans rarely match reality and that unanticipated issues, such as a gas leak discovery while on the job, can affect the work scheduled to be performed.

Following the call to the national call-before-you-dig number 811, and the marking of the buried utility lines by the utilities, a work site has been properly staged for reviewing those locations and determining the best method for excavating. That determination is made based on answers to the following questions:

• What further geotechnical investigation work is scheduled for the site?

• What surface cover will need to be cut? Grass, asphalt, concrete?

• What type of soil is present?

• How much workspace is available for equipment access?

• What is the anticipated density of buried services?

Careful consideration of each unique jobsite and vacuum excavation best practices will support job productivity and mitigate risks.

Seeing is Believing

With the right tools at the job site, utility excavation is ready to safely begin. Again, using utility markings as “suggested” locations, the goal of excavation should be to visually locate the buried utility lines. Vacuum excavation is advantageous and known as “safe digging” because it allows the contractor to proceed using air and/or water to excavate in the ground in the marked locations until the facilities are visually identified. Vacuum excavation best practices define the pressure of air or water used, as well as the type of nozzle, based on excavation depth and soil conditions. The Gas Technology Institute (GTI) is a leading independent non-profit research, development, and training organization instrumental in establishing and publishing the most up-to-date trenchless best practices for damage prevention. GTI supports ongoing research and develops new tools and techniques for reducing excavation damage. New technology is available to prevent water system pressure from exceeding site or industry requirements and effectively eliminates human error in the excavation equation to provide increased safety.

TRUVAC® brand vacuum excavators are designed to support these safe practices and reduce risks inherent in underground utility location. Whether a job is a new installation, or repair to existing underground infrastructure, contractors will benefit from using marked utility locations as merely “suggested” locations, or a guide map to the construction area. Safe digging with non-destructive vacuum excavation will provide visual confirmation of the location of buried utilities and contribute to increased productivity on the job and smarter digging designed to be more profitable for contractors.

Underground utilities were exposed quickly and efficiently using a combination of air and hydro vacuum excavation to provide visual location of underground utilities.

Underground utilities were exposed quickly and efficiently using a combination of air and hydro vacuum excavation to provide visual location of underground utilities.

This article first appeared in Trenchless Technology Magazine, January 2022